PROPERTIES

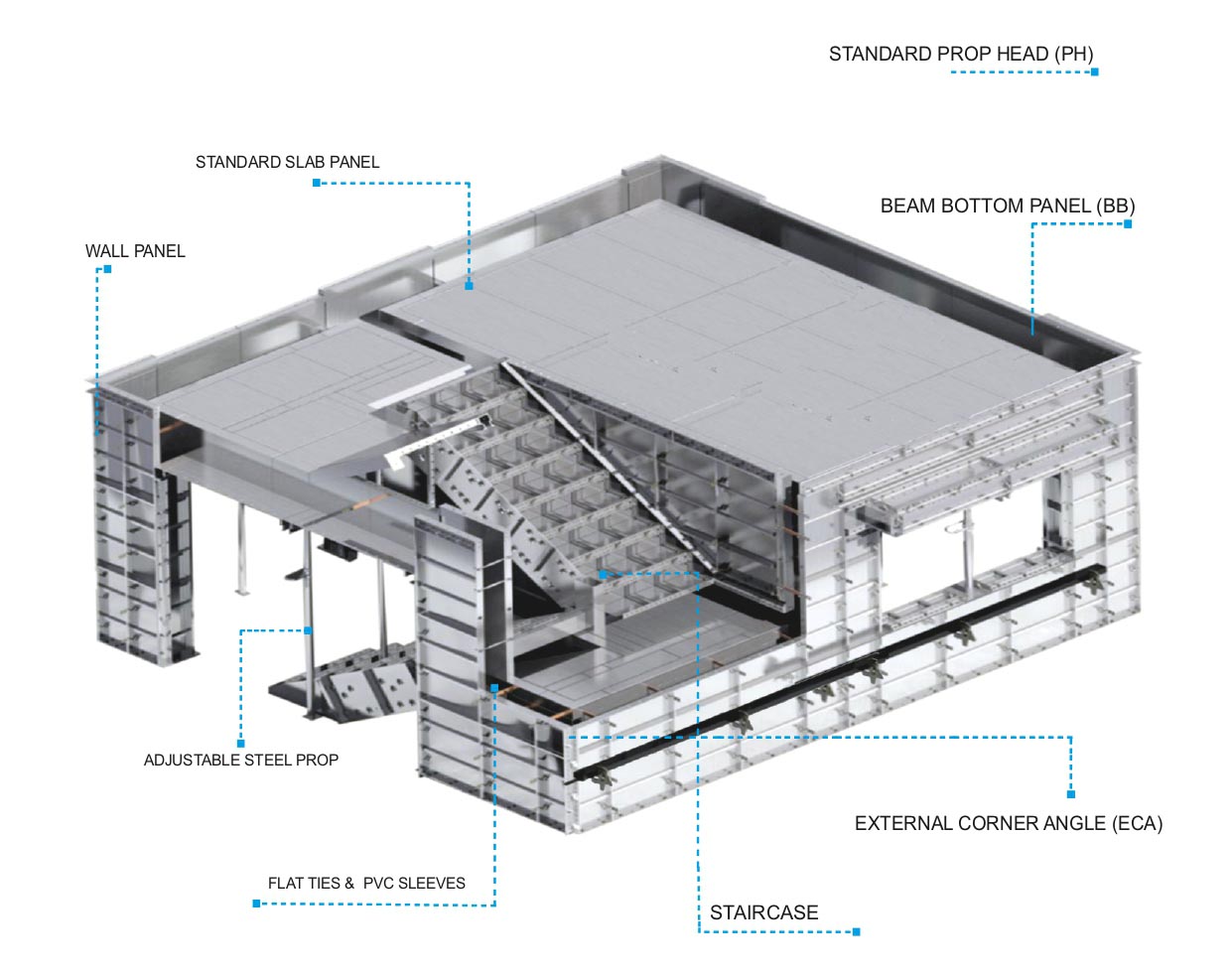

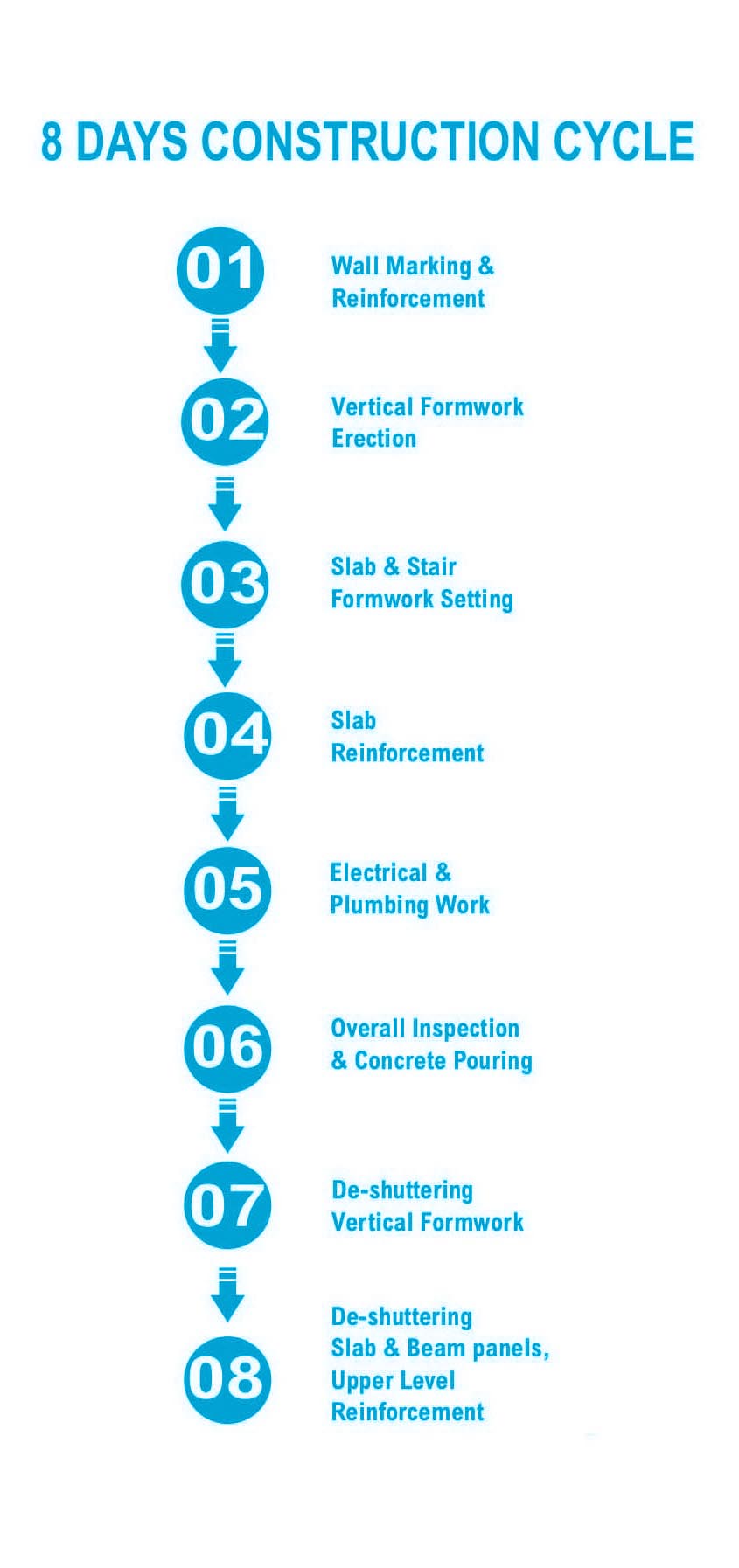

SRR ALUMINIUM FORMWORK SYSTEM

The most important aspect of a successful structural construction is the formwork system SRR will always offer you the most trustworthy, secure, efficient and cutting edge of formwork system technology available in the market.